Your Current Position: NEWS

- In the merchandise operation system of Sam's Club, the design style of palletized selling is not "one-size-fits-all". Following Style A, today we focus on Containment Trays, detailing the palletizing specifications for products such as cans, bottles, and boxes, to help suppliers accurately grasp compliance details.

- In today's competitive retail landscape, strategic product placement is non-negotiable. Businesses need solutions that are not only visually compelling but also operationally superior. This is where the strategic business application of PDQ Pallet Displays becomes a critical component of successful in-store marketing and logistics.A PDQ (Pretty Darn Quick) Pallet Display is more than just a temporary stand; it is a versatile, high-impact tool designed to solve multiple business challenges across various industries. Let's explore the key commercial applications that make it an indispensable asset.

- In the fast-paced world of retail, capturing consumer attention is half the battle. Brands are constantly seeking innovative, cost-effective solutions to stand out on the crowded sales floor. Enter the PDQ Pallet Display – the ultimate "speed-to-market" solution that is revolutionizing in-store marketing.

- In the efficient operation of Sam's Club, palletized selling is a key link to ensure the aesthetic display of products, stable transportation, and customers' shopping experience. Today, we will focus on the boxed products design style to comprehensively analyze the specification requirements and best practices of Sam's palletized selling, helping supplier partners to efficiently and compliantly launch products on the shelves.

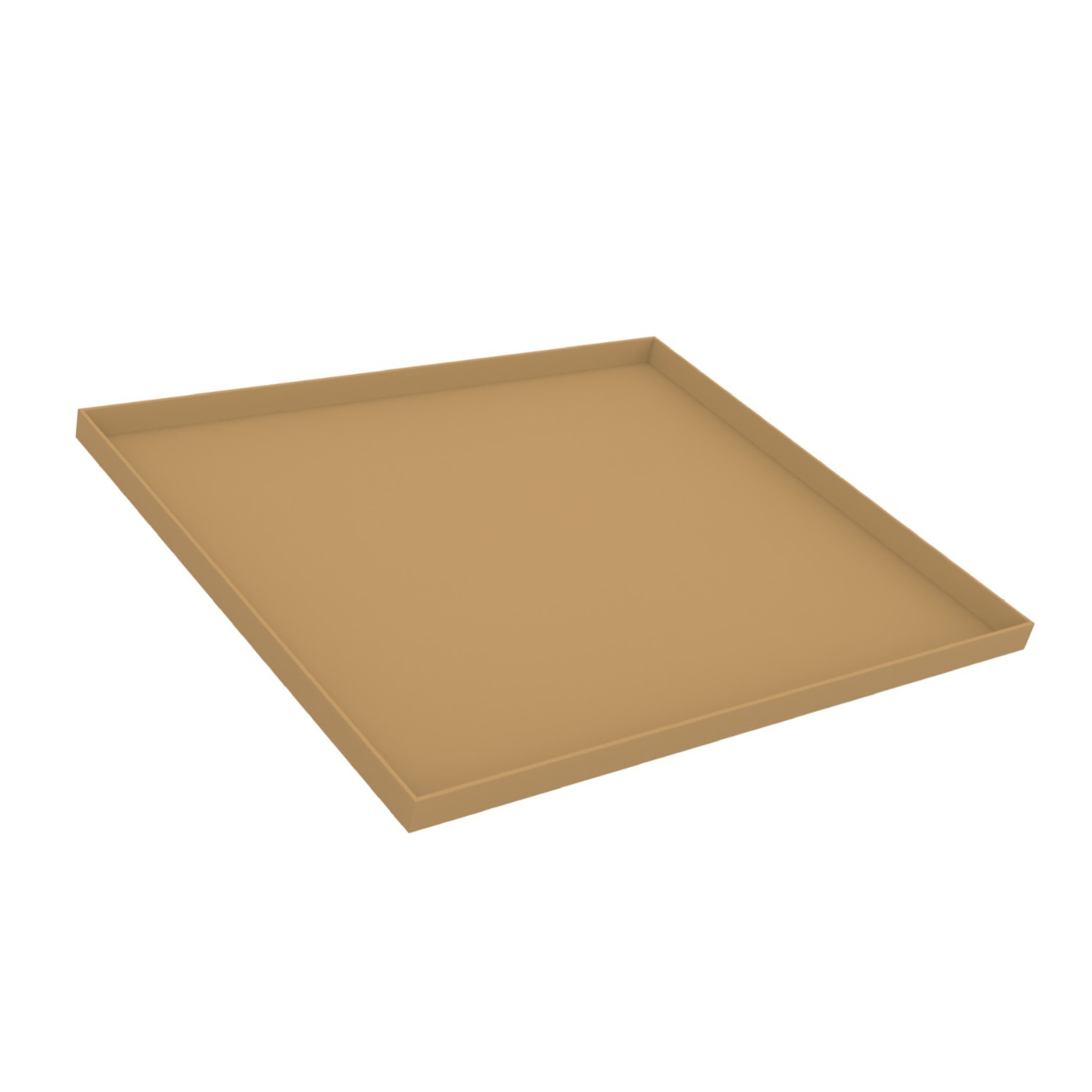

- In the POD (Product Display) system, "top and bottom cover" is a common split box structure. It is a component used to protect, enclose, and enhance products in POD bulk pallet packaging or independent display packaging. Its core features consist of two parts: the "top cover" (and the "bottom cover"), which work together to cover and secure the product.

- In the fast-paced world of logistics and retail packaging, efficiency and cost-effectiveness are always top priorities. If you’re involved in supplying international retailers like Sam’s, Walmart, or Costco, you’ve probably heard of slip sheets— the innovative alternative to traditional wooden or plastic pallets that’s revolutionizing POD (Proof of Delivery) bulk tray packaging. But with two main material options on the market—kraft paper slip sheets and plastic slip sheets—how do you choose the one that fits your business needs? Let’s break it down.

- 2025-10-14In today's fast-paced logistics and retail environment, speed, accuracy, and presentation are not just advantages—they are absolute necessities. The traditional methods of shipping palletized goods often fall short, leading to delays at receiving docks, damaged products, and frustrated retailers. This is where the innovative concept of **PDQ Pallet POD** comes into play, revolutionizing the way products move from distribution centers to store shelves.

- A PDQ Pallet Display is a highly efficient, self-contained merchandising unit designed for retail environments. The acronym "PDQ" stands for "Pretty Darn Quick," highlighting its core benefit: rapid deployment from the shipping pallet to the sales floor with minimal assembly.These displays are an integrated marketing tool that combines a sturdy base (often the shipping pallet itself), a branded structure, and the product inventory into a single, cohesive unit. Their primary purpose is to function as a high-impact, point-of-purchase (POP) display, strategically placed in high-traffic areas like store aisles or endcaps to capture shopper attention.

- 2024-10-02Design considerations cover target audience alignment, product advantage highlighting, brand image consistency, striking visuals, rational space use, easy product identification, durable materials, convenient restocking, innovation, cost control, adaptability to sales environments, and clear display of product info, price and promotions. As a type of POD packaging, it’s often seen in warehouse-style international retailers (e.g., Sam's, Costco, Walmart, Kmart, Target, Lowe's, The Home Depot, Walgreens, Price Smart), with a warehouse-like display style compared to ordinary domestic supermarkets.

- A PDQ stackable display is a display tool for showcasing products quickly, where "PDQ" stands for "Product Display Quickly".

- 2024-09-18As a special display and packaging method, POD (Product on Display) has been widely used in warehouse-style stores in recent years. It places products directly on display at sales terminals. Its core is to showcase products as a whole via well-designed display plans, enabling intuitive and attractive presentation to boost exposure, sales and consumers’ purchase desire.

- The cost of POD (Packaging on Demand) full-tray packaging is influenced by various factors, primarily including materials, design complexity, transportation methods, and additional services.

National service hotline:+86(0)755-2898 7706

National service hotline:+86(0)755-2898 7706

.jpg)

.png)

.png)