For lightweight products that cannot support weight (such as apparel, towels, and bagged goods), Sam’s PDQ Stacking Trays are the dedicated solution—ensuring stability during transportation and display while enabling a convenient shopping experience. Today, we break down the full-process requirements of PDQ Stacking Trays, covering tray types, design specifications, and product compatibility.

1. Core Types of PDQ Stacking Trays

PDQ offers 3 basic tray configurations to suit different display scenarios:

- Stacking Tray – Palletized: Standard full-pallet stacking model, ideal for bulk warehousing and large-area in-store displays.

- Stacking Tray – 3 Side Shop: 3-side shoppable model, enhancing member convenience when selecting products.

- Stacking Tray – Single Stack/Inline: Single-column stacking model, suitable for narrow aisles or small-area displays in stores.

2. Non-Negotiable Compliance Requirements for PDQ

All PDQ trays must strictly adhere to the following rules:

1. Shoppability: At least 3 sides must be shoppable; if a tray contains only 1 or 2 selling units, ensure the tray shoulders do not block the product.

2. Weight & Dimensions: Single tray weight ≤ 50 lbs; no overhang, total underhang ≤ 3 inches, and unit footprint ≥ 45” × 37”.

3. Packaging Performance: Selling units and secondary packaging must pass ISTA-6 SAMSCLUB transit testing; false bottoms are prohibited.

4. Special Scenarios: For coolers/freezers, corrugated boards must use Moisture Resistant Adhesive (MRA) to prevent warping from moisture.

5. Transit Protection: Top shipping caps or top sheets are required to protect the top layer during transit.

3. Tray Design & Structural Specifications

PDQ trays balance "load support" and "usability," with key design requirements including:

PDQ trays balance "load support" and "usability," with key design requirements including:

- Stacking Support: Non-supportive products (e.g., bagged, vacuum-sealed goods) must include stacking features (liners, dividers, etc.); corrugated flutes must be oriented vertically to enhance load strength.

- Display Modules: The front panel height of master display modules ≤ 3 inches (and ≤ 1/3 of the module height), with no obstruction of product information; display cases must open by hand (no tools required), and opening features must not compromise shipping performance.

- Material Standards: Corrugated board must be at minimum 32 ECT B-flute or 200 lb. Mullen; tear tape is prohibited, and tape may not be used on the member-facing portion of the display.

- Detail Protection: The front lip must be tall enough to prevent false scoring; thumb holes for easy opening must be knocked out during die-cutting (with a ¼” cut to the left of the right hole); perforated windows should be designed to tear away from the front lip toward the top of the case to minimize front lip damage.

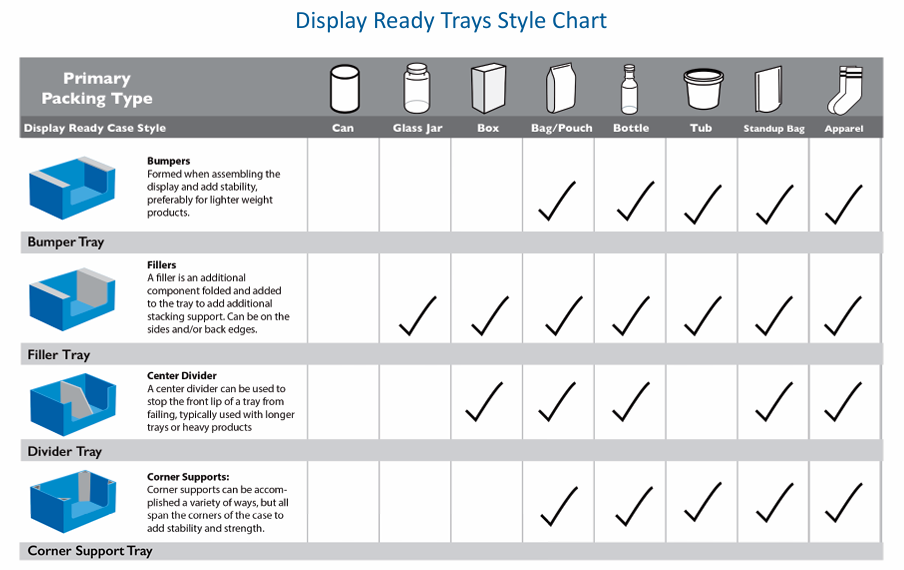

4. Product Compatibility Chart for Tray Structures

Different tray structures correspond to specific product types—use this reference to match appropriately:

PDQ Stacking Trays are Sam’s "customized solution" for lightweight products. Strictly following these specifications prevents product damage

in the supply chain and ensures neater, more efficient in-store displays.

For more questions related to Sam's Club packaging solutions, please consult CTK!

National service hotline:+86(0)755-2898 7706

National service hotline:+86(0)755-2898 7706